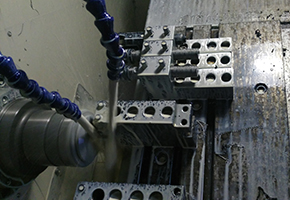

Ka baaraandegista qaybaha nylon ee ku yaal lathe

Get Latest Price| Nooca Bixinta: | L/C |

Tusaale ahaan.: PL-097

Sababta oo ah qaybo ka mid ah qaybaha NYLON -ka ayaa leh mid aan sun lahayn, oo ah culeys khafiif ah, xidho iska caabbinta caabbinta iyo caabbinta wanaagsan, oo ka mid ah soosaarka iyo soosaarka, budada bamka iyo qaybaha kale ee mashiinka , warshadaha kiimikada, aaladda, baabuurta iyo warshadaha kale. Marka mashiinka naaska lagu xiro , dhibaatada ugu weyn ayaa ah in la xalliyo cilladaha goynta. Qaybaha nylon ee caadada ah waa mid jilicsan oo fudud in la gooyo, laakiin sidoo kale waa fududahay in la carqaladeeyo. Marka mashiinka natbon lagu xidho , goynta xagal waaweyn oo xagal ah, jeexan ballaadhan oo goyn ah iyo radius caarada yar waa in la xushaa. Marka labaad, dharbaaxada hawada ayaa loo isticmaali karaa qaboojinta. Intaas waxaa sii dheer, fiiro gaar ah waa in la siiyaa si loo xidho, iyo xoojinta xayiraaddu waxay noqon doontaa labis intii suurtagal ah. Qaar ka mid ah gacmaha khafiifka ah ee gacmaha lagu xirto ayaa loo isticmaali karaa marka lagu dhex tuuro nylon oo ku yaal lathe .

Waxaan leenahay koox farsamo u go'an oo ah TCNC. Hab-yaqaannada Warshadaha: Dib u eegista Amarka, Dib-u-eegista Sawirka, Barnaamijka Wax Soo Saarka, Qorshaynta Wax Soosaarka, Qorshaynta Wax Soosaarka, Ganacsiyada, Baadhitaanka Tayada, Baakadaha iyo Gaadiidka. Shaqaalaheena farsamada ayaa urursan khibrad farsamo oo badan oo ku saabsan mashiinnada caagga ah ee caagga ah, waxaan ku leenahay falanqayn faahfaahsan oo ku saabsan cilladaha sheyga ee ka dhaca caabada ee CNC . Inta badan dhammaan CNC ee qaabilaada geedi socodka balaastigga ah, shaqaaluhu wuxuu sameyn doonaa in lagu hor dhigo inuu xakameeyo cilad-gelinta sheyga.

Dhismaha Kooxda Dhismaha, Ltd ayaa had iyo jeer loo tixgeliyaa tayada sidii aasaaska u tartamaya Tartanka shirkadda, iyada oo loo marayo nidaamka hagaajinta adag iyo xakameynta tikniyoolajiyadda tayada leh, iyada oo ku saleysan dhammaan dhinacyada ay ku raacsan yihiin heerka tayada sare.

|

Business content |

CNC miliing, CNC turning |

|

Machining Processes |

CNC Milling, CNC Turning, CAM Programming, Sheet Metal Fabrication, Grinding, Cutting, Thread Turning, Milling Threading, Tapping, Drilling, Knurling |

|

Machining Metal |

Titanium, Aluminum, Copper, Brass, Bronze, Stainless Steel, Steel, Delrin, Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, PEEK, Acrylic, PMMA,PC, Polycarbonate, PAI, PPS, PA, PET, PEI, PE, PVC, PP, ABS, PEP, PS, PSF, PI, PMMI, PABM, PU. |

|

Parts Size |

Milling Parts ( MAX) : Length 1030mm,Width 800mm, Height 750mm. Turning Parts ( MAX) : Diamter 680mm,Length 750mm. |

|

Tolerance |

0.01mm |

|

Equipment Capabilities |

CNC Machining Center, 3 Axis, 4 Axis, CNC Lathe, Lathe, CNC Turning Centers, Horizontal 8/12-position hydraulic turret, Milling Machine, Grinding Machine, Drill Press, Tapping Center, Rotary Indexer, Punch |

|

Secondary Services of Machining Parts |

Assemble, Plating Zinc Color (Machining Steel Parts), Anodize, Anodize Color, Hard Anodize, Hard Anodize Teflon (Machining Aluminum), Electroless Nicke (Machining Aluminum Parts, Machining Stainless Steel Parts, Machining Brass Parts ), Passivation ( Machining Stainless Steel parts ), Sand Blasting ( Machining Aluminum parts ), Brushed ( Machining Aluminum parts , Machining Stainless Steel parts ), Bluing and Blackening ( Machining Steel parts ), Trivalent Chromium Process ( Machining Aluminum parts ), Welding, brazing, soldering, Centerless Grinding and Burnishing |

|

Sample |

Samples are for free, sample time is 5 days. |

|

Delivery |

Delivery time is 3-4 week, depending on the degree of difficulty of machining parts |

|

file format |

Para-Solid 3D, PDF, IGES, STEP, SOLIDWORKS |

Waxaan rajeyneynaa inaan sii wadno xiriir dheeraad ah. Hayso maalin wanaagsan oo waad ku mahadsan tahay weydiimahaaga!

Bayaanka Asturnaanta

Buuxi macluumaad dheeri ah si markaa si dhakhso leh ula xiriiri karto

Bayaanka Asturnaanta