Caadada u roga bir bir khafiif ah

Get Latest Price| Nooca Bixinta: | T/T |

| Madadaalo: | FOB |

| Min. Dalbo: | 1 Bag/Bags |

| Gaadiidka: | Ocean,Land,Air |

| Nooca Bixinta: | T/T |

| Madadaalo: | FOB |

| Min. Dalbo: | 1 Bag/Bags |

| Gaadiidka: | Ocean,Land,Air |

Tusaale ahaan.: MS-019

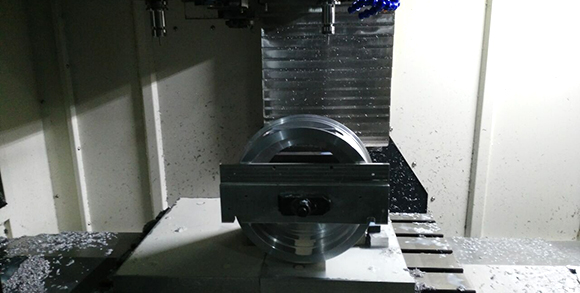

Caadada u roga bir bir khafiif ah

Markaad leexdo bir khafiif ah, haddii jabinta chip-ka khafiifka ah uusan sameyn karin xagal xiirid ah oo ku filan oo ka go'ay godka goynta, waxay soo saari doontaa cabitaan dheer, oo waxay u soo saari doontaa burooyinka muddada dheer dusha sare ee dusha sare ee shaashadda. Xawaare hooseeya oo u roga bir khafiif ah waa sabab kale oo loogu talagalay uruurinta qashinka. Chip Dhismuhu wuxuu door ka ciyaari doonaa furitaanka aaladda kordhinta, sidaasna loo beddelo cabirka mashiinnada qaybaha, oo dusha sare ayaa ka sii dari doona. Xaaladdan oo kale, markii aad u leexaneyso bir khafiif ah waxa ay lagama maarmaan tahay in la kordhiyo xawaaraha goynta illaa 15% - 20% ama ka badan illaa tayada dusha sare ee qaybaha birta ee caadiga ah.

Iyada oo ah dukaanka farsamada ee caado ee CNC, waxaan u isticmaalnaa qaybaha takhasuska ah ee ka baxsan wixii alaab ah ee cayiman, heer loo maro heerka qalaad.

|

Machining Aluminum |

6061, 6061-T6, 6063, 7075, 5052, 2024, 2017, 6082 |

|

Machining Copper |

Copper, Brass, Bronze |

|

Machining Stainless Steel |

SUS303, SUS304,( 56645627, 56150081, 54800234, 54155620,1.4301), SUS316 |

|

Machining Steel |

Q235, 45 #, A3, 718H, S136, SKD11 |

|

Machining Titanium |

|

|

Machining Plastic |

Delrin, Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, Peek, PMMA, PC, PAI, PPS, PA, PVDF, POM, PA, PET, PEI |

Intaas waxaa sii dheer, waxaan sidoo kale bixinnaa alaabo loogu talagalay adeegyadaaga dugsiga sare: ururin, qaybo bir ah oo zinc ah ah), alodize, alumininium-ka adag (mashiinka aluminium), mashiinnada aluminis-ga Qeybo, mashiinka naxaasta ah), mashiinka naafada ah), mashiinka nasashada (mashiinka loo yaqaan 'steel-ka', qaybo aluminium ah (mashiinnada aluminium), mashiinnada birta birta ah), mashiinnada birta ah (mashiinnada chromium) Qeybaha), alxamida, ciriiri, miyir-beel, shiilid oo aan kala go 'lahayn iyo gubasho.

Guul darrooyinka degdega ahi waa faa'iidoteena. Waxaan ku dhameysan karnaa muunadda isu beddelka qaybaha 3 maalmood gudahood. Haddii aad u baahatid, waxaan ku dhameysan karnaa tusaalaha tusaalaha maalin gudaheed, sidoo kalena bixin karno adeega farsamada. Warshaddayadu waxay bixisaa 2 ~ 3 Xarunta Iskaha ee CNC, oo si gaar ah loogu isticmaalo muunadaha mashiinnada. Shaqaalaha warshaddaheena waxay u qaybsan yihiin laba koox si ay u hubiyaan in mashiinku uu soo saarayo badeecada 24 saacadood.

Noocyada kaladuwanaanshaha ee farsamooyinka hubaysan ayaa noo oggolaanaya inaan macaamiisheenna siino qiimaha ugu fiican ee soo saarista qaybo bir ah oo loo yaqaan '' Iyada oo aan loo eegin cabirka ama caddeynta amarkaaga, waxaan haysannaa qalab aan shaqada ku qaban karo oo aan soo saari lahayn qeybahaaga goorta iyo sida aad ugu baahan tahay.

Bayaanka Asturnaanta

Buuxi macluumaad dheeri ah si markaa si dhakhso leh ula xiriiri karto

Bayaanka Asturnaanta