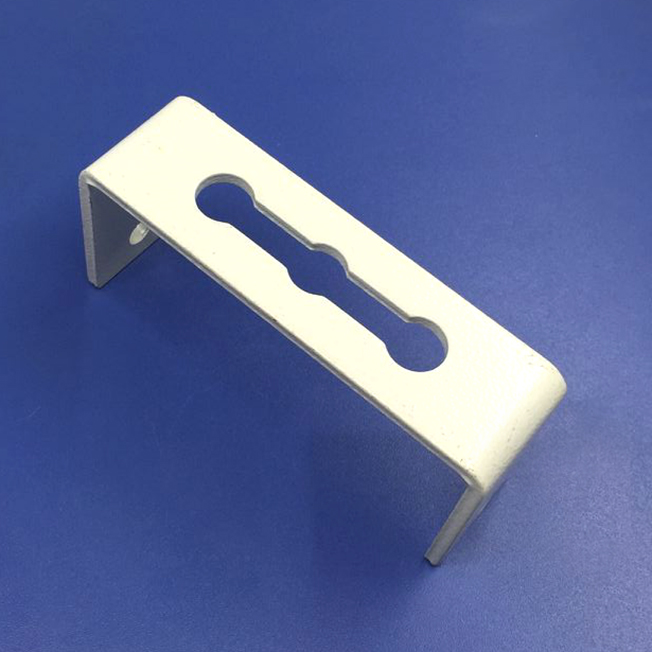

Xaashida birta ee caadada ah

Get Latest Price| Min. Dalbo: | 1 Bag/Bags |

| Gaadiidka: | Ocean,Land,Air |

Tusaale ahaan.: SM-002

Soosaarka birta ee xaashida waa adeegsiga wax soo saarka birta ee chimney, baaldi, haanta, tuubbada biyaha, geedka ugu dambeeya, alxanka, giveting, waxay u baahan tahay aqoon gaar ah joomatari. Talaabooyinka Birta Biraha ee Mareemka: Imtixaanka hordhaca ah ee soosaarka, soosaarka wax soo saarka wax soo saarka iyo wax soo saarka dufcadda. Tallaabada wax soo saarka ee wax soo saarka birta ee xaashida ah, waa in si dhakhso leh ula xiriirtaa taabashada macaamiisha, ka hel qiimeynta ku habboon ee laxiriira, ka dibna wax soo saarka dufcadnimo. Xaashida birta ee caagga ah guud ahaan loo isticmaalo ashyaa waa saxan qabow, saxan kulul, saxan, naxaas, sida ay u kala dooranayaan agabyo kala duwan, guud ahaan wax soo saarka badeecada iyo Qiimaha kor u qaadida.

Shirkaddayadu waa qaybo sax ah oo wax soo sareeya oo wax soo saarta shirkada, shirkadda si adag u dhaqan geliso nidaamka maaraynta tayada tayada ISO si loo hubiyo tayada, in la sameeyo qaybo keli ah iyo qaybo badan oo ay ku taliyaan ganacsi. Macaamiisha waaweyn ee qalabka dhismaha, caafimaadka, maraakiibta, militariga, baabuurta, baabuurta, sheybaarada sayniska iyo beeraha kale. Waxaan bixinaa warshadaha-warshadaha caadada ah ee CNC ee loo jeediyo iyo milking. Bixinta ugu fiican ee CNC ee ugu fiican iyo dhagaxa toosan ee CNC / Tooska ah. Maraakiibtayaga ballaaran ee casriga ah ee CNC-ga farshaxanada casriga ah iyo makiinadaha is-beddelka CNC waxay la kulmaan dulqaadka ± 0.01mm. Iyada oo loo marayo wadashaqaynta iyo isgaarsiinta carruurta, waxaan sare u qaadnaa nidaamka maamulka, waxaan ku dhejinaa muhiimadda macaamiil kasta, si aan u hubinno in CNC-ga kasta oo ka mid ah mashiinnada ka mid ah tayada iyo dhalmada.

|

Business content |

CNC miliing, CNC turning |

|

Machining Processes |

CNC Milling, CNC Turning, CAM Programming, Sheet Metal Fabrication, Grinding, Cutting, Thread Turning, Milling Threasing, Tapping, Drilling, Knurling |

|

Machining Metal |

Titanium, Aluminum, Copper, Brass, Bronze, Stainless Steel, Steel, Delrin, Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, PEEK, Acrylic, PMMA,PC, Polycarbonate, PAI, PPS, PA, PET, PEI, PE, PVC, PP, ABS, PEP, PS, PSF, PI, PMMI, PABM |

|

Parts Size |

Milling Parts ( MAX) : Length 1030mm,Width 800mm, Height 750mm. Turning Parts ( MAX) : Diamter 680mm,Length 750mm. |

|

Tolerance |

0.01mm |

|

Equipment Capabilities |

CNC Machining Center, 3 Axis, 4 Axis, CNC Lathe, Lathe, CNC Turning Centers, Horizontal 8/12-position hydraulic turret, Milling Machine, Grinding Machine, Drill Press, Tapping Center, Rotary Indexer, Punch |

|

Secondary Services of Machining Parts |

Assemble, Plating Zinc Color (Machining Steel Parts), Anodize, Anodize Color, Hard Anodize, Hard Anodize Teflon (Machining Aluminum), Electroless Nicke (Machining Aluminum Parts, Machining Stainless Steel Parts, Machining Brass Parts ), Passivation ( Machining Stainless Steel parts ), Sand Blasting ( Machining Aluminum parts ), Brushed ( Machining Aluminum parts , Machining Stainless Steel parts ), Bluing and Blackening ( Machining Steel parts ), Trivalent Chromium Process ( Machining Aluminum parts ), Welding, brazing, soldering, Centerless Grinding and Burnishing |

|

Sample |

Samples are for free, sample time is 5 days. |

|

Delivery |

Delivery time is 3-4 week, depending on the degree of difficulty of machining parts |

|

file format |

Para-Solid 3D, PDF, IGES, STEP, SOLIDWORKS |

Bayaanka Asturnaanta

Buuxi macluumaad dheeri ah si markaa si dhakhso leh ula xiriiri karto

Bayaanka Asturnaanta