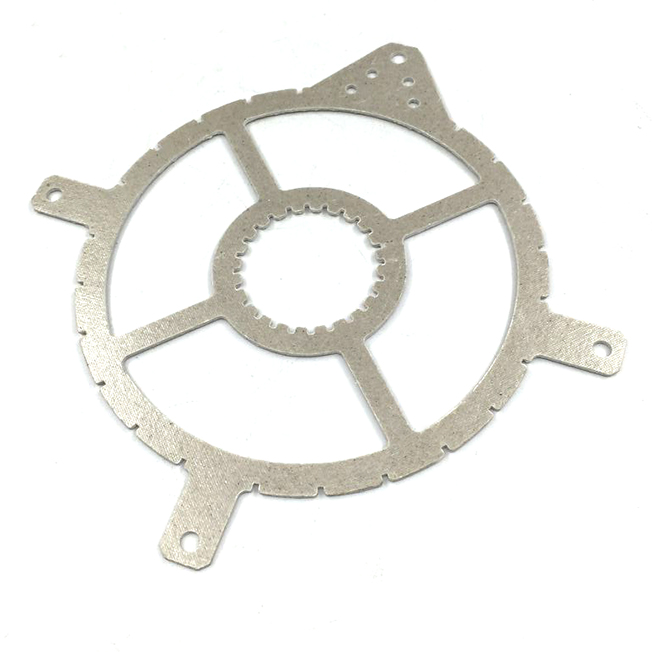

Xaashiyaha Xaashida Maska ah ee Miisaaniyadda

Get Latest Price| Nooca Bixinta: | T/T |

| Madadaalo: | FOB |

| Min. Dalbo: | 1 Bag/Bags |

| Gaadiidka: | Ocean,Land,Air |

| Nooca Bixinta: | T/T |

| Madadaalo: | FOB |

| Min. Dalbo: | 1 Bag/Bags |

| Gaadiidka: | Ocean,Land,Air |

Tusaale ahaan.: SM-010

Xaashida xaashida caadada ah ee caadada ah waxay ka kooban tahay warqadda Migga iyo unugyada alosicon-ka, kuleylka, la riixayo, micnaha micnaha, waxay ka kooban tahay nuxurka xabagta ee asaafada ah waa 10%. Xaashida loo yaqaan 'Xaashida Dambiila ee caadada' waxay leedahay guryo xiisa badan oo koronto ah, alaabooyin caan ah oo ka hortagaya burburka korantada ayaa ah mid ka sarreeya 20kv / mmv / mm. Qaybaha xaashida khafiifka ah ee miciolka ah waxay leeyihiin guryo badbaado oo heer degmo ah, sheygu kuma jiro asbestos, marka uu kululeeyo qiiqa ka yar, oo urkuna waa yar yahay, iyo xitaa qiiq la'aan, oo aan caqabado lahayn, oo aan cabbin. Qeybaha qatadka khafiifka ah ee Mica Mic Mica waxay leeyihiin iska caabin heer sare ah oo loo adeegsado xaaladaha heerkulka sare ee loo isticmaalo heerkulka heerkulka ayaa wali hayn kara wax qabadkiisa asalka ah, heerkulka ugu sareeya ayaa la gaarey 1000 ℃, oo ah waxyaabo aad u heer sare ah. Midaynta Micaka Sides waxeey si balaadhan loogu isticmaalaa garoonka korantada, sida bir qalajiyaha ah, dheriga timaha, kuleylka microwave, sida foornada ee foornada, sida soo noqnoqda dhexdhexaadka ah Foorsadda, foornada arc, mashiinka caqabadaha duritaanka, iwm ..

Shirkaddayadu waa qaybo sax ah oo wax soo sareeya oo wax soo saarta shirkada, shirkadda si adag u dhaqan geliso nidaamka maaraynta tayada tayada ISO si loo hubiyo tayada, in la sameeyo qaybo keli ah iyo qaybo badan oo ay ku taliyaan ganacsi. Macaamiisha waaweyn ee qalabka dhismaha, caafimaadka, maraakiibta, militariga, baabuurta, baabuurta, sheybaarada sayniska iyo beeraha kale. Waxaan bixinaa warshadaha-warshadaha caadada ah ee CNC ee loo jeediyo iyo milking. Bixinta ugu fiican ee CNC ee ugu fiican iyo dhagaxa toosan ee CNC / Tooska ah. Maraakiibtayaga ballaaran ee casriga ah ee CNC-ga farshaxanada casriga ah iyo makiinadaha is-beddelka CNC waxay la kulmaan dulqaadka ± 0.01mm. Iyada oo loo marayo wadashaqaynta iyo isgaarsiinta carruurta, waxaan sare u qaadnaa nidaamka maamulka, waxaan ku dhejinaa muhiimadda macaamiil kasta, si aan u hubinno in CNC-ga kasta oo ka mid ah mashiinnada ka mid ah tayada iyo dhalmada.

|

Business content |

CNC miliing, CNC turning |

|

Machining Processes |

CNC Milling, CNC Turning, CAM Programming, Sheet Metal Fabrication, Grinding, Cutting, Thread Turning, Milling Threasing, Tapping, Drilling, Knurling |

|

Machining Metal |

Titanium, Aluminum, Copper, Brass, Bronze, Stainless Steel, Steel, Delrin, Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, PEEK, Acrylic, PMMA, PC, Polycarbonate, PAI, PPS, PA, PET, PEI, PE, PVC, PP, ABS, PEP, PS, PSF, PI, PMMI, PABM |

|

Parts Size |

Milling Parts ( MAX) : Length 1030mm,Width 800mm, Height 750mm. Turning Parts ( MAX) : Diamter 680mm,Length 750mm. |

|

Tolerance |

0.01mm |

|

Equipment Capabilities |

CNC Machining Center, 3 Axis, 4 Axis, CNC Lathe, Lathe, CNC Turning Centers, Horizontal 8/12-position hydraulic turret, Milling Machine, Grinding Machine, Drill Press, Tapping Center, Rotary Indexer, Punch |

|

Secondary Services of Machining Parts |

Assemble, Plating Zinc Color (Machining Steel Parts), Anodize, Anodize Color, Hard Anodize, Hard Anodize Teflon (Machining Aluminum), Electroless Nicke (Machining Aluminum Parts, Machining Stainless Steel Parts, Machining Brass Parts ), Passivation ( Machining Stainless Steel parts ), Sand Blasting ( Machining Aluminum parts ), Brushed ( Machining Aluminum parts , Machining Stainless Steel parts ), Bluing and Blackening ( Machining Steel parts ), Trivalent Chromium Process ( Machining Aluminum parts ), Welding, brazing, soldering, Centerless Grinding and Burnishing |

|

Sample |

Samples are for free, sample time is 5 days. |

|

Delivery |

Delivery time is 3-4 week, depending on the degree of difficulty of machining parts |

|

file format |

Para-Solid 3D, PDF, IGES, STEP, SOLIDWORKS |

Astaamaheena:

Bayaanka Asturnaanta

Buuxi macluumaad dheeri ah si markaa si dhakhso leh ula xiriiri karto

Bayaanka Asturnaanta